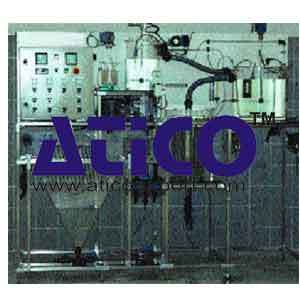

Sewage Treatment Pilot By Nitrification – Denitrification – Dephosphatisation

Teaching Objectives of

Sewage Treatment Pilot By Nitrification – Denitrification – Dephosphatisation

- To understand the degradation phenomena of organic and chemical pollutants by the action of the micro-organisms in an aerobic environment followed by a physico-chemical treatment.

- Operation of a treatment plant according to sampling and daily analyses.

- Characterization of the nitrification – denitrification – dephosphatisation stages.

Technical specifications

- An anoxia tank with stirrer

- A ventilation tank with measurement of pH, temperature and dissolved oxygen,

- A clarification conical tank device with recuperation of the sludge

- A compressor controlled by oxygen rate measurement.

- A resistance (heater) dependant of temperature measurement,

- A dosing pump for basic solution controlled by pH measurement.

- A substrate supply pump.

- A sludge recycling pump.

- A recycling pump for the main solution

- An air flowmeter

- A liquid flowmeter for the substrat

- A laminate decanter, with adjustable plates, made of three compartments that fill themselves by overflow from the clarification device :

- A tank for the coagulation – stirred flocculation,

- A tank for the enlargement of the flakes,

- A tank for the decantation by overflow for the treated water

- A tank for the preparation of flocculation agent and coagulant (the reagents) mounted on the magnetic stirrer

- A pump for the reactants dosing

- A control panel with instrumentation and controls

- The unit is mounted on a stainless steel frame.

Dimensions

- 2 200 x 700 x 2 000 mm.

Essential requirements

- Power supply : 220 V / single phase / 50 Hz