Ion Exchange Pilot

Teaching objectives

- According to the analysis of the water and flow to be treated or the desired quality to obtain, one can choose.

- The resin to test.

- The type of regenerating.

- The quantity of regenerating.

- The flow and function type (co-current, counter-current).

- Measuring the resin capacity according to the regeneration and then calculation the material balances (Ca²+, TH, TA, TAC).

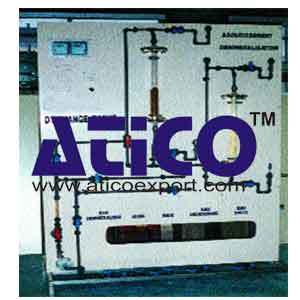

Technical specifications

- Two Altuglass columns (for regeneration)..

- Two Altuglass columns (for processing).

- The columns are removable to change the resins.

- 1 litre of anionic resin.

- 1 litre of cationic resin.

- 1 polypropylene centrifugal pump.

- 5 transparent PVC tanks.

- 1 Conductivity measuring sensor with digital display.

- Five measuring sensor layouts. The measuring sensors are moved in the layouts according to the chosen processes.

- Two fluid circuits to feeding the columns either in co-current or counter-current mode.

- Control panel including a synoptic with diodes to improve the circuit understanding according to the different regeneration /processing stages. It includes the pump control and safety protection, the conductivity measuring transmitters. All the piping is in PVC, the pilot is mounted on a stainless steel frame.

Option :

- Another conductivity measuring sensor with digital display

Dimensions

- 1400 x 800 x 1900 mm

Essential requirements

- Power supply : 220V / single phase / 50 Hz – Power consumption : 80 W.

- Strong cationic resin : Purolite C100 – Strong anionic resin : Purolite A200 HCI 5%, NaOH 5%.