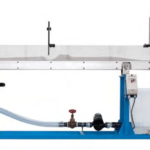

The individual steps for repairing driven machines such as pumps are: removal and installation of pumps for inspection, repair or replacement; aligning the drive and commissioning and checking the pump, e.g. For leaks. In conjunction with the tank system, the connecting pipes and one of the four pumps, the assembly stand forms a complete training system for complex piping and plant systems. The training system forms a closed water circuit.

Learning Objectives And Experiments

- In conjunction with an accessory pump (standard chemicals pump, canned motor pump , side channel pump, standard chemicals pump with magnetic clutch) and a suitable water supply,

- Mounting of the pump and alignment of the electric motor

- Familiarisation with various methods of aligning the motor and pump

- Commissioning and leak testing

- Recording a pump characteristic

- Comparison of various pump types (only if multiple pumps are available)

Features

- Mounting of different pumps (available as accessories)

- Alignment of motor and pump by different methods

- Base unit when constructing a complex piping system

Specification

- Stand for mounting of various pumps

- Asynchronous motor with variable speed via frequency converter

- Electric motor with positioning frame and fit plates for alignment

- Base plate prepared for mounting of various pumps

- Alignment of motor and pump with straight-edge or by dial gauges

- Switch box with speed adjuster and digital display of speed and power output

- Frame with adjustable feet for levelling

- PVC piping

- Water supply from tank system

The system forms part of the assembly, maintenance and repair practice line

Technical Specification

- Three-phase AC asynchronous motor

- Power output: 4kw, speed range: 0…1450min-1

- Connecting flanges for water supply

- Intake side: DN50

- Delivery side: DN50

- Intake side channel pump: DN32

- Fit plates as motor chocks

- 43x43mm

- 4 different thicknesses: 0,1 – 0,2 – 0,5 – 1,0mm, 20 of each

- Measuring ranges

- Pressure (inlet): ±1bar

- Pressure (outlet): 0…16bar

- Flow rate: 0…11m3/h

- Speed: 0…3000min-1

- Power: 0…4kw

- Travel: 0…3mm, resolution: 0,01mm

- 400V, 50Hz, 3 phases

- 400V, 60Hz, 3 phases; 230V, 60Hz, 3 phases