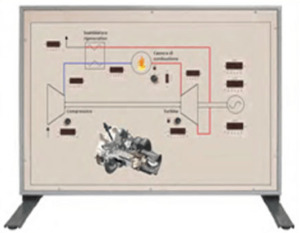

Many of the electric energy production plants adopt the turbo gas technology. The simplest type of gas turbine system is a single shaft line and consists of multistage compressor (extracted air from the outside is compressed), combustion chamber (combustion of fuel added to the compressed air) and turbine (expansion of the gas coming from the combustor occurs). The power developed in the expander is partly absorbed by the compressor and the remaining part it is supplied to the coaxial electric generator. A considerable amount of heat is dissipated in the environment; therefore often the solution is adopted with regenerative heat exchanger for the recovery of heat from the gas leaving the turbine, which go to preheat the combustion air entering the liner of the combustion chamber.

The simulator properly studies the type of system just described.

TRAINING PROGRAM

The simulator is proposed as a theoretical-practical synthesis of two fundamental topics of modern technical physics:

• Turbo-gas plant thermodynamic:

– construction of plant scheme

– calculation of thermodynamic efficiency

– dynamics of circulating air (compression and expansion)

– sizing of combustion chamber

– example of a cycle with exhaust gas recovery

• Electric propulsion:

– calculation of propulsion power required

– gas turbine design model

– gas turbine off-design model

– examples of typical expanders (single and multi-stage)

– electric drives

TECHNICAL SPECIFICATIONS

The simulator consists of:

• Desktop vertical panel that works together with a PC (not included)

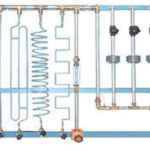

• Color screen-printed plate reproducing the cross section of a gas turbine, showing the layout of the propulsion elements

• Electrical checks

• Display for basic parameters

Software

The supplied software allows the panel parameters view and the settings modification.

Selectable specifications:

• Air flow setting by potentiometer

• Fuel flow setting by potentiometer

• Shaft power setting by potentiometer

• ON-OFF power generator via analog button

• Switch for integration with regenerative exchanger

Programmable specifications

• On-design operation:

– INPUT: air and fuel flowrate

– OUTPUT: power generation

• Off-design operation:

– INPUT: air flowrate and mechanical power

– OUTPUT: fuel flowrate

• Turbo-expansion: possibility to choose 3 different types of turbine.

• Combustion: possibility to choose 3 different types of combustion chamber with 3 different fuels.

• Thermal recovery: possibility to choose 2 different heat exchangers with different performance.

• Power supply: 230 Vac 50 Hz single-phase – 400 VA (Other voltage and frequency on request)