Description

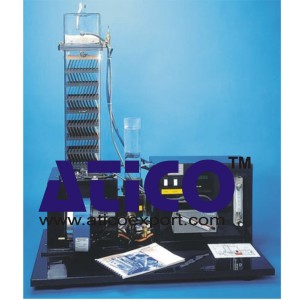

The Computer Controlled Water Cooling Tower has been designed to give students an appreciation of the construction, design and operational characteristics of a modern evaporative cooling system. The unit is also an excellent example of a specialised heat exchanger, where two streams of fluid flow (water and air) are brought into direct contact and in which there is a mass transfer from one phase to the other.

The comprises a cooling tower mounted on top of a heated water reservoir. The cooling tower is manufactured from clear acrylic for visibility, and has an easily removable front face to allow different packing materials to be inserted.

Features:

Measurements, computer control and data logging via USB port as standard

Closed loop PID control of water temperature at entry to the tower for more versatile operation and more accurate results

Four interchangeable sections of tower packing material supplied

Two densities of packing material included for comparison

Three different heights of packing can be compared

User supplied material can easily be fitted into the tower for project work

Uses true industrial packing material for more representative demonstrations

Improved distribution of water onto the packing using an array of spray nozzles

Electronic (software) control of water recirculation, air flow and heater power

Electronic sensors measure flow of air and water, temperature of air and water and humidity entering and leaving the packing

Modern electronic humidity sensors utilized, eliminating the need for high maintenance wet and dry bulb thermometers

Water loss due to evaporation measured electronically

Can be operated as a simple spray tower with no packing installed

Specification:

Bench top unit to demonstrate operation of a forced draught cooling tower

Computer controlled, supplied with Windows software

Clear acrylic tower for visibility, dimensions 700 mm x 150 mm x 150 mm

Removable front panel on the tower, allowing different packing materials to be tested

Supplied with four blocks of industrial packing material giving two different packing densities and three different packing heights

Full height of packing 500 mm

Water reservoir with 1.75 kW (nominal) electrical heater

Closed loop PID control of water temperature or constant power operation of the heater, variable from 0 to 1.75 kW (nominal)

Software controlled variable speed water pump adjustable from 0 to 2.4 l/min

Software controlled variable speed air blower adjustable from 0 to 65 g/s

Electronic instrumentation includes flow of air and water, temperature of air and water and RH of air entering and leaving the packing